The shaker screen is one of the most critical yet vulnerable parts of a shaker. Its performance directly affects the efficiency and product quality. Due to varying operating conditions and material properties, the replacement cycle of the screen can differ.

1) Material characteristics &

workload:

When separating abrasive or highly adhesive materials, the

screen experiences increased wear from friction and impact. Under heavy

duty conditions, some screens may last only 2–3 weeks, while under milder

conditions, their lifespan may extend to 6 months or more.

2) Quality & installation:

Premium screens use high-quality materials and proper pre-tensioning to ensure

even load distribution. Improper installation, such as insufficient tension,

may lead to accelerated wear or tearing.

3) Vibrating motor & operating :

The motor’s direction, vibration amplitude, and feed amount directly

affect the screen’s conditions. Incorrect motor direction or overfeeding can

increase wear on the screen.

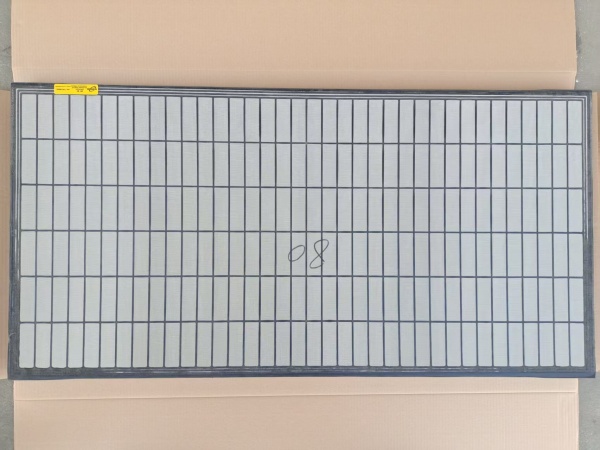

1) Visual inspection:

Regularly inspect the screen surface for visible cracks, broken wires, or

holes—especially along the edges and tension bars where damage is more likely.

2) Tension assessment:

Check if the mesh has become slack, wavy, or depressions. The

screen should be tightly fitted to the frame.

3) Screening efficiency observation:

If oversized particles appear in the output or there is an abnormal increase in

fines in the undersize, this could be due to the openings deformed or blocked.

4) Operational feedback:

Operators should be alert to any abnormal vibrations, loud noise, or a

noticeable drop in production efficiency, as these may be linked to

screen wear.

Regular inspections: Conduct quick visual checks daily or at the end of each shift,

and perform detailed inspections weekly.

Adjust tension promptly: If appears slack, adjust the tension

immediately to ensure even force distribution.

Operate correctly: Ensure the motors are set to the

proper direction, with an appropriate amplitude, avoid overfeeding.

Choose quality products: Use high-quality screens with proper

pre-tensioned and select products suited for the operating conditions.

For any questions or further technical

support, feel free to contact our service team.