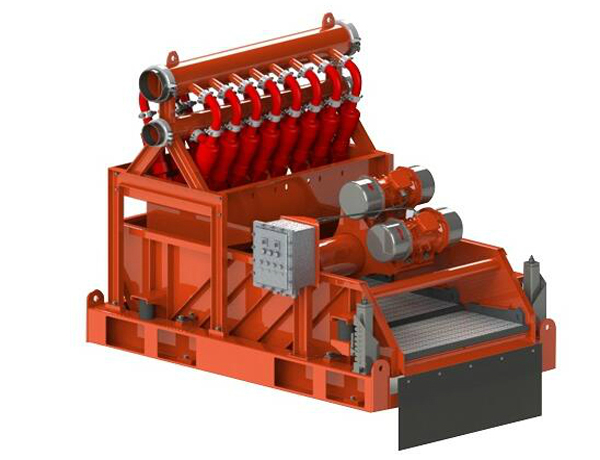

Shale Shaker

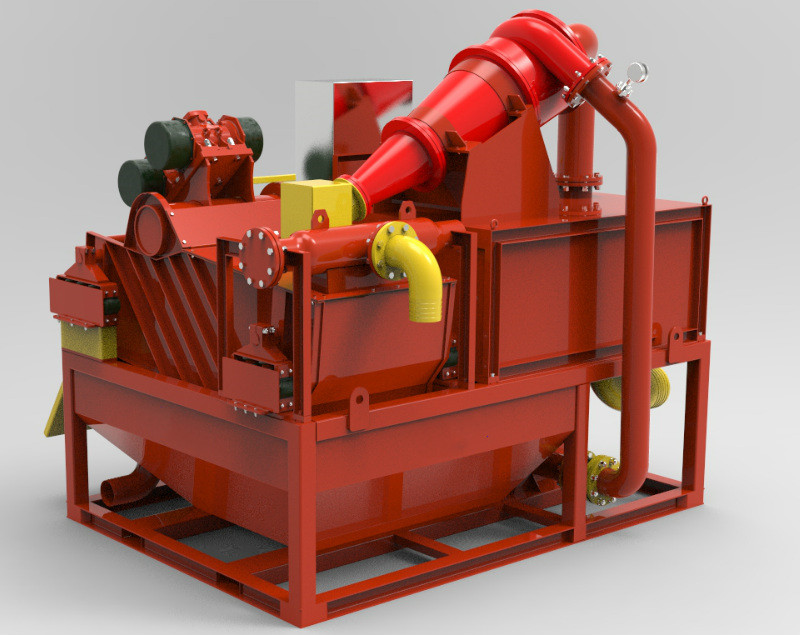

Our range of versatile shale shakers is designed to cater to various drilling requirements. Our shakers ensure efficient cutting separation from two panels for small rigs to four panels for oil drilling, with options like high-G dryers and vertical cuttings dryers.

Product Features

High-Performance Shale Shakers for Varied Drilling Needs

The shale shaker has different configurations to work with different drilling requirements. The two-panel shaker can work for small rig drilling operation. The three-panel shaker can work with oil drilling / water well drilling / HDD. The four-panel shaker can work for oil drilling operation / waste management to achieve much dryer drilling cuttings.

When working for drilling cuttings treatment, high G dryer or high G shaker is normally requested. Lower operation cost, lower maintenance cost, the oil on cuttings can be reduced to about 10 ~20%. In some other drilling operations, the owner may require to reduce the OOC below 3~5%, and we recommend Vertical cuttings dryer to achieve this target.

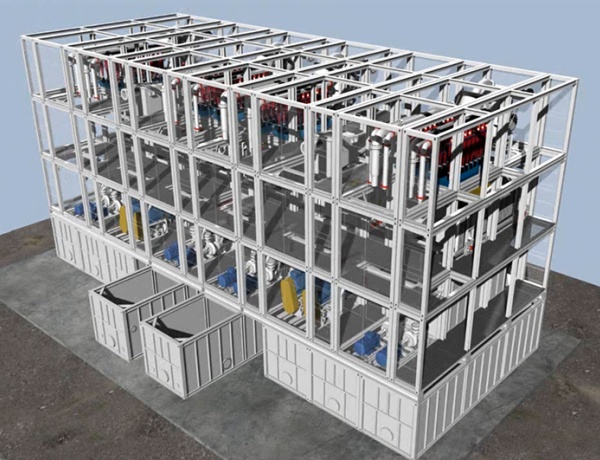

Drilling Mud Shale shaker is the first phase screening machinery in solids control system. With over 10 years of experience in design and manufacturing, KES Separation’s heavy-duty shale shaker is capable of operating in most hazardous areas for both onshore and offshore drilling activities.

Technical Parameters of Flat screen Shale Shaker:

| Model | KSZS112-MM | KSZS113-MB | KSZS114-MP | KSZS114-MD |

| Vibrating Mode | Linear motion | Linear motion | Linear motion | Linear motion |

| Max. Capacity (m3/h) | 70 | 110 | 140 | 140 |

| Vibrating Motor (kw) | 2×0.75 | 2×1.5 | 2×1.72 | 2×1.94 |

| Adjusting G force (G) | ≤7.0G | ≤7.5G | ≤7.5G | ≤8.0G |

| Vibration Amplitude (mm) | 3.92~5.62 | 4.14~5.96 | 4.4~6.34 | 4.4~6.34 |

| Deck Adjustment | +2° | -2°~+5° | -2°~+5° | -2°~+5° |

| Screen Qty (pcs) | 2 | 3 | 4 | 4 |

| Screen Size(mm) | 750×900 | 585×1165 | 585×1165 | 585×1165 |

| Screen Area (m2) | 1.35 | 2.04 | 2.73 | 2.73 |

| Weir Height (mm) | 710 | 885 | 885 | 885 |

| Weight (kg) | 893 | 1340 | 1553 | 1520 |

| Dimension(mm) | 1715x1360x1090 | 2322x1650x1400 | 2912x1650x1425 | 2650x1650x1425 |

Technical Features of Flat screen Shale shaker:

- Liner Motion, Balance Elliptical Motion and Dual Motion available.

- Capable to deal with heavy mud in large feeding capacity

- Shaker deck angle adjustable while working, mechanical deck angle adjustment with reliable performance.

- Shale shaker bottom deck made from Stainless Steel for long service life.

- Heat treatment on complete shale shaker deck for High G force operation.

- Pretension shaker screen for fast screen replacement, shaker size equivalent to Swaco Mongoose

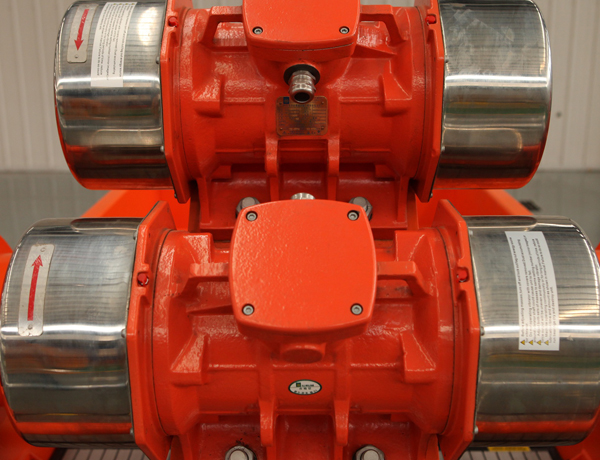

- Famous Brand Vibration Motors: Italy OLI or US Martin brand motors

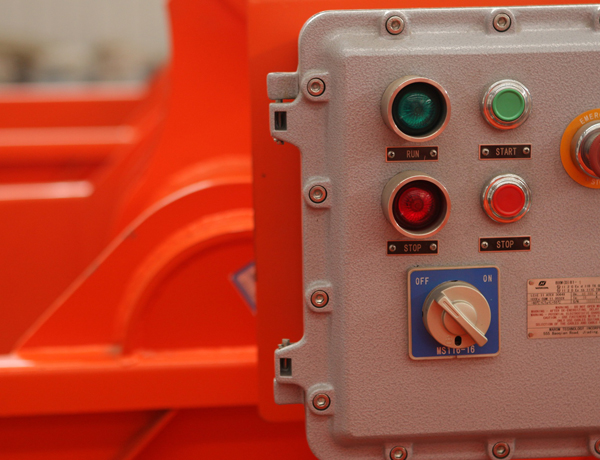

- Main electrical components is sourced from premium brands: SIEMENS, Schneider or ABB available

- Different type shaker available for different applications

FAQ:

- What are the main types of Shale Shakers offered by KES Separation?

KES Separation offers various configurations, including two-panel shakers for small rigs, three-panel shakers for oil, water well, and HDD drilling, and four-panel shakers optimized for oil drilling and waste management, aiming for drier cuttings.

- What are the key features of KES Separation Shale Shakers?

Our Shale Shakers feature Liner Motion, Balance Elliptical Motion, and Dual Motion options. They can handle heavy mud with large feeding capacity, have an adjustable deck angle (even while working), and are built with a durable Stainless Steel bottom deck and heat-treated complete deck for high G-force operation. They also use pretension shaker screens for quick replacement and are equipped with renowned vibration motors (Italy OLI or US Martin) and premium electrical components (SIEMENS, Schneider, or ABB).

- What are the benefits of using KES Separation Shale Shakers?

Using our Shale Shakers can significantly lower operation and maintenance costs. They are designed to reduce oil on cuttings (OOC) to as low as 10-20%, and when paired with a Vertical Cuttings Dryer, can achieve OOC levels below 3-5%.

- In what applications can KES Separation Shale Shakers be used?

Our Shale Shakers are widely used in Oil & Gas Drilling, Foundation Construction, Mining Sludge, and Municipal Sludge. They are integral to Oil Drilling Mud Systems, Oily Sludge Separation, Drilling Cuttings Systems, WBM Treatment Systems, Frac Water Treatment Systems, Mud Water Separation, HDD Mud Systems, and Shield Slurry Systems.