Vertical Cutting Dryer

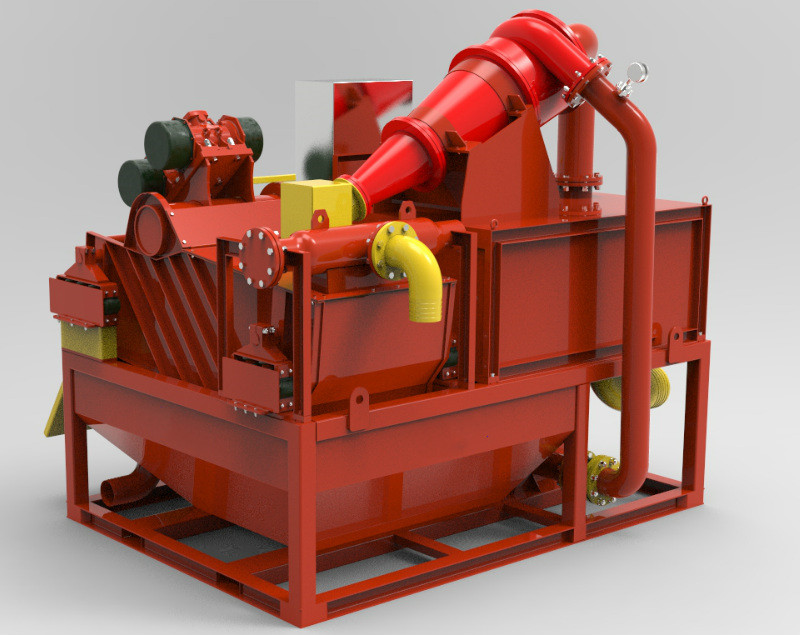

The main function of vertical Cuttings dryer is to recover the useful oil based mud, reduce the oil content on cuttings (OOC) and reduce the total volume of cuttings which will be finally treated by Thermal Desorption Unit.

Product Features

On-line Drilling Cuttings is generated from the whole drilling process. The cuttings will be carried out by drilling fluids, and then separated by solids control / waste management systems. The first stage separating equipment is shale shaker. After shaker separation, the fine cuttings will drop down to under tank with drilling fluids, and the coarse cuttings will be separated and treated by vertical cutting dryer.

The main function of vertical dryer is to recover the useful oil based mud, reduce the oil content on cuttings (OOC) and reduce the total volume of cuttings which will be finally treated by Thermal Desorption Unit. The recovered oil based mud will be returned to active mud system. Some conditions, the operator will adopt High G dryer or high G shaker to replace the Vertical dryer to achieve same functions. Even, the performance of High G dryer is not as good as Vertical Cutting Dryer, the oil on cuttings will be around 10% after high G dryer, but all choices is depends on the client requirements.

Technical Parameters of Vertical Dryer

| Model | KSCD930C-FS | KSCD930C-VFD |

| Max. Treating capacity (ton/h) | 30-50 | 30-50 |

| Drying efficiency | OOC≤ 5% | OOC≤ 5% |

| Screen Diameter(mm) | 930 | 930 |

| Screen opening size(mm) | 0.25/0.35/0.5 | 0.25/0.35/0.5 |

| Cone angle | 30° | 30° |

| Screen rotation speed(rpm) | 900 | 0~900 VFD |

| Separation G force (max) | 420G | 420G |

| Main Motor(kw) | 55 | 55 |

| Oil Pump Motor(kw) | 0.55 | 0.55 |

| Flush pump(kw) | 3~4 | 3~4 |

| Oil Tank Capacity (L) | 48 | 48 |

| Air Knife Pressure(Mpa) | 0.69 | 0.69 |

| Air Knife Flow (m3/min) | 1.8 | 1.8 |

| Weight (kg) | 4600 | 4600 |

| Dimension(mm) | 2650×1800×1650 | 2650×1800×1650 |

Technical Features of Vertical Dryer

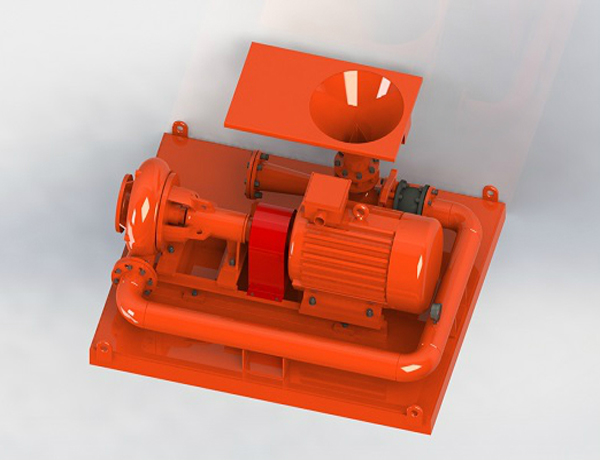

420G High G force under 900 rpm regular operation speed

750G High G force under 1200 rpm higher operation speed for option

Vertical Cutting Dryer can be started with fixed speed control or VFD control

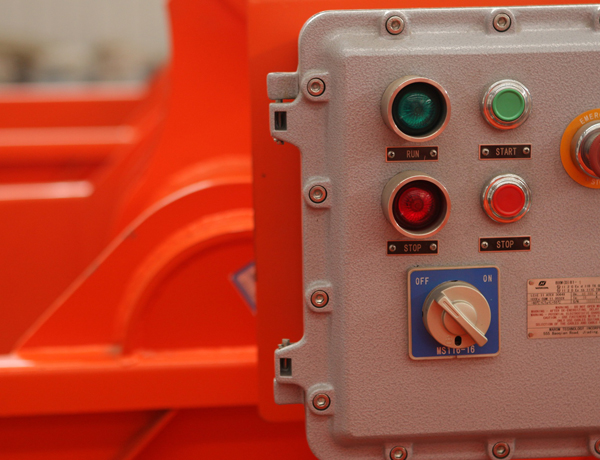

Main electrical components sourced from international brand: SIEMENS, Schneider or ABB

The Ex-proof standard normally comply with China Standard EXDIIBT4, IEC/ATEX for option

The main bearings are Spherical Roller Bearings, source from FAG Brand

The Flights on the rotor is hard facing to HRC 65, with longer lifetime

The Flights and the rotor assembly are individually balanced for easy replacement

The screen basket material is Stainless Steel 316L, better performance in ani-corrosion

The screen basket is processed in high precision and dynamic balance to ensure better balance and easy replacement

Equipped with high pressure air cutter to clean the high viscosity mud sticking on the screen basket

Equipped with water jetting system to work together with air cutter, to avoid screen block

Individual oil lubrication system with low pressure automatic alarm.

Dryer motor and oil system motor is interlocked, the dryer can be started only after starting the oil pump