Recently, KES Separation successfully shipped a customized 10-ton forklift to Nigeria after completing all inspection and quality verification procedures. This 10tons Forklift is customized for cuttings box(mud skip) transportation and unloading, aiming to solve the transfer challenges in local cuttings treatment and support environmental protection work in oil drilling and related industries.

The forklift adopts a modular design, consisting of four core components: body, mast, forks and rotator. The body, as the foundation, has a high-strength load-bearing frame to adapt to outdoor operating conditions in Nigeria. The mast, made of wear-resistant steel, undertakes the lifting function stably. The forks are precisely matched to the size of cuttings boxes (which also purchased from KES Separation) with anti-skid reinforcement to avoid offset during transportation. The rotator, a key unloading part, can rotate flexibly at multiple angles to realize rapid dumping.

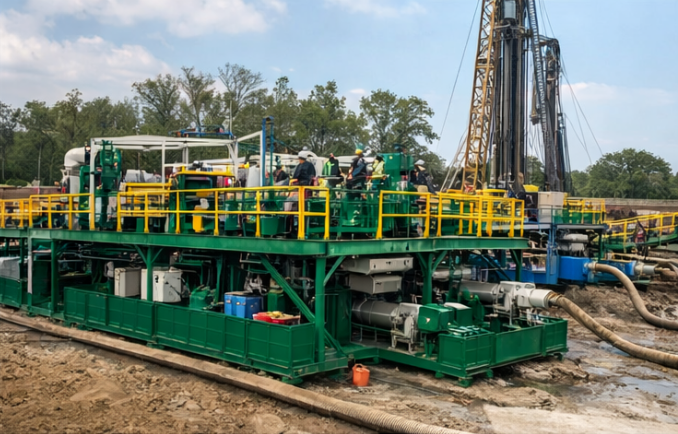

Its core purpose is to transport and unload cuttings boxes in oil drilling operations. In actual work, solid cuttings processed by vertical cutting dryers or decanter centrifuges and other solids control equipment are collected into cuttings boxes. When full, the forklift will fix the box through the forks, transport it to the designated area stably, unload by adjusting the box angle via the rotator, and then return the empty box for recycling. The unloaded cuttings will be further transported to Thermal Desorption Unit (TDU) for harmless treatment before final compliant discharge.

To meet local outdoor heavy-load operation needs, the forklift is optimized in performance parameters. Its maximum lifting height reaches 3 meters, suitable for stacking and loading cuttings boxes. The maximum lifting weight is 10 tons, capable of carrying heavy boxes full of cuttings, matching the local large-displacement cuttings treatment intensity.

Nigeria is an important oil drilling market in Africa, with urgent demand for environmental protection treatment of drilling wastes such as cuttings. This shipment is an important measure for KES Separation to explore the overseas market. The size/volume of KESS cuttings box (mud skip) is customized per customer requirement. KESS offshore cuttings box is DNV2.7-1: 2017 and EN12079 Certified by DNV or LR.

During offshore drilling, the OBM cuttings will be generated continuously. As the OBM cuttings is contaminate and is not allowed to discharge into the sea; the OBM cuttings can be shipped back to onshore through offshore mud skips. After that, the OBM cuttings with slops can be send to Thermal desorption unit for final treatment. If the OBM slops with high percentage oil, the OBM slops can go to Oil sludge separation unit to recover the oil first. After the oil recovery, the solids phase can go to TDU.

Offshore Mud Skip is popular applied in offshore drilling industry and other offshore industry. The size/volume of mud skip is customized per customer requirement. The roof normally should be Aluminium material for for lightweight and easy opening and closing. Four sides forklift holes will be designed for easy movement; Polyurethane Anticorrosive Paint for Marine Box, much longer lifetime. We can also customize 20ft cuttings box, size similar to 20ft container. KES Separation offers not just the cuttings boxes and containers, but a bespoken turn-key solution for the entire drilling waste management loop.

Welcome to contact us for your customized offshore equipment requirements.