Starch Processing

- Home /

- Food & Beverage /

- Starch Processing

Starch is a versatile raw material fundamental to the food, paper, and chemical industries. Whether processing tubers like potatoes and tapioca or pulses like peas, profitability depends on three critical factors: maximum yield, minimized water consumption, and premium product quality. KES industrial centrifuges are engineered to master these challenges by efficiently separating starch and protein components, dewatering fibers to reduce drying costs, and recycling process water to lower environmental impact.

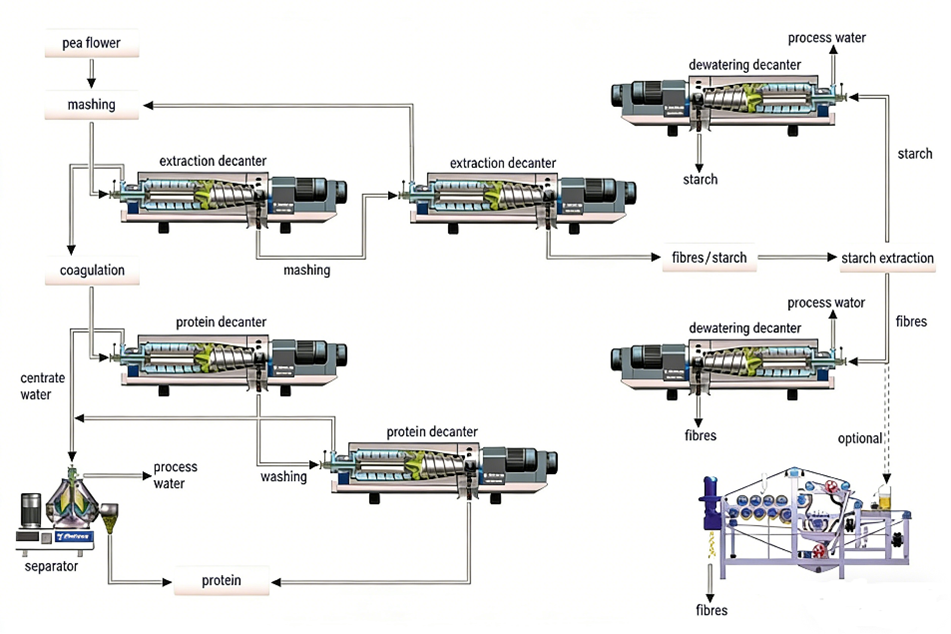

Pea Starch and Protein Recovery

Peas offer high value through both starch and functional protein. The processing challenge lies in separating fine starch particles from the protein-rich liquid phase while managing fibers. KES Decanter Centrifuges excel in the extraction step, separating the starch/fiber mixture from the “fruit water” containing dissolved proteins. This ensures a high yield of pure starch while providing a clean protein stream for further isolation.

Potato Starch and Fruit Water Separation

In potato starch production, speed is paramount to prevent oxidation and ensure product whiteness. KES Decanters serve a dual purpose here: they dewater potato pulp to a high dry solids content for use as animal feed This allows producers to recover high-quality potato protein from what was previously a waste stream, maximizing the value of every tuber.

Key Application Areas

Casein Production

Production of casein involves acid precipitation followed by washing. KES Decanters are utilized to separate the curd from the whey and subsequent wash water. Our technology efficiently reduces wash water consumption while delivering a dry casein curd, significantly lowering downstream thermal drying costs.

Lactose Processing

In the crystallization of lactose, KES Decanters separate the crystals from the mother liquor. The robust wear protection on our scrolls ensures long operational life even when handling abrasive lactose crystals, ensuring continuous and reliable separation performance.

Calcium Phosphate Extraction

Recovering calcium phosphate (DCP) from whey creates an additional revenue stream and facilitates whey demineralization. KES Decanters efficiently separate these fine precipitates under specific thermal conditions, optimizing the value extracted from the whey stream.

Contact Us

Ready to Optimize Your Starch Production? With extensive experience in separation technology, KES is your partner for efficient, sustainable, and profitable starch processing.