Dairy Processing

- Home /

- Food & Beverage /

- Dairy Processing

Hygienic Separation for the Dairy Industry

In dairy processing, product safety and hygiene are the absolute baselines. However, profitability is driven by the ability to recover every drop of value from the milk stream. KES offers a comprehensive portfolio of sanitary Decanters and Disc Stack Separators designed to clarify whey, dewater casein, and recover valuable milk fats.

Our equipment is engineered for gentle processing to protect sensitive milk fat globules and proteins, ensuring premium product quality while maximizing yield.

Whey Clarification & Cheese Fines Recovery

Turning By-products into Profit

In cheese production, the “steeping water” or whey often contains residual cheese fines. KES provides a dual-stage solution to recover these solids while clarifying the water for reuse or disposal.

The Process Flow: The process begins with a buffer tank and heat exchanger. The KES Separator first clarifies the liquid, separating the cheese fines from the water/cream phase. The concentrated cheese fines are then fed into a KES Decanter for final dewatering, producing a dry, valuable solid product.

High-Efficiency Fat Concentration

Wash water from butter production or other dairy streams often contains valuable milk fats. Recovering this fat requires precise centrifugal force to separate phases of varying densities.

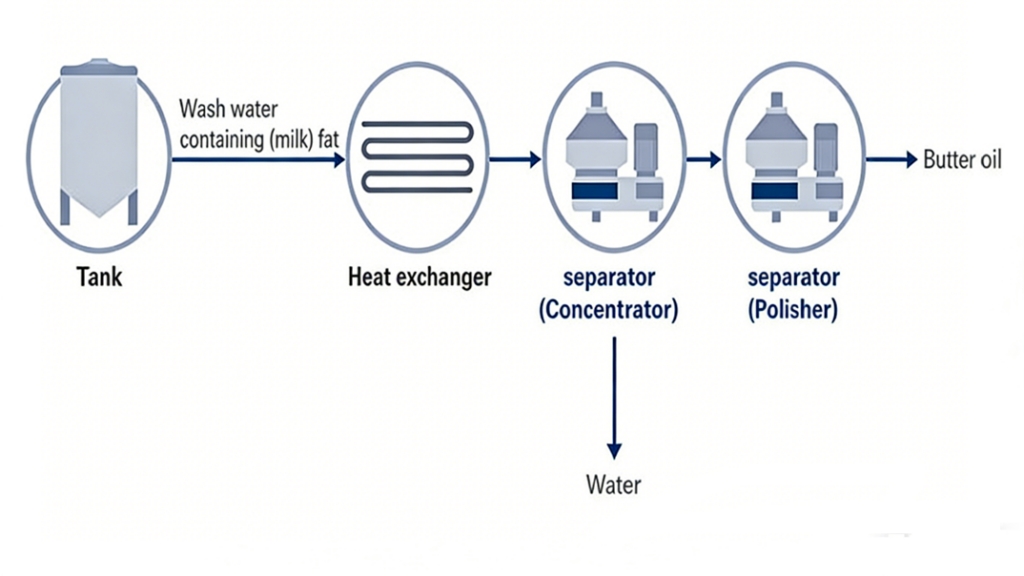

The Process Flow: The wash water containing milk fat is heated and sent to a 2-stage separation system.

- Concentration:The first KES Separator (Concentrator) removes the bulk of the water, creating a concentrated fat phase.

- Polishing:The second KES Separator (Polisher) further purifies the fat phase to produce high-quality Butter Oil.

Key Applications

Casein Production Production of casein involves acid precipitation followed by washing. KES Decanters are used to separate the curd from the whey and subsequent wash water. Our technology efficiently reduces wash water consumption while delivering a dry casein curd, lowering drying costs.

Lactose Processing In the crystallization of lactose, KES Decanters separate the crystals from the mother liquor. The robust wear protection on our scrolls ensures long operational life even when handling abrasive lactose crystals.

Calcium Phosphate Extraction Recovering calcium phosphate (DCP) from whey is a growing revenue stream. KES Decanters efficiently separate these fine precipitates under specific thermal conditions, enabling whey demineralization.

Customer Benefits: The KES Hygiene Standard

- Premium Sanitary MaterialsDairy environments require frequent cleaning with acids and bases. KES bowls are centrifugally cast from Duplex Stainless Steel 2205 or 2304, offering superior corrosion resistance compared to standard 316L, ensuring longevity under CIP conditions.

- Gentle & Smart ControlTo prevent shearing of sensitive milk fats, speed control is critical. Our systems use an Ex-proof VFD control panelwith PLC smart control and Yaskawa converters. This allows precise, independent regulation of the bowl and scroll speeds to match the delicate nature of dairy products.

- Top-Tier ReliabilityContinuous dairy operations cannot afford downtime. We utilize genuine SKF bearingsand premium electrical components from Siemens, Schneider, and ABB to ensure maximum machine availability and operational stability.

- Fully CIP CompatibleAll KES dairy centrifuges are designed for Clean-in-Place (CIP)capability. The open frame design and sanitary finishes ensure no dead zones for bacteria, meeting the strictest international food safety standards.

Contact Us

Ready to Optimize Your Dairy Line? Contact our sanitary process experts to discuss how KES separation technology can increase your yield and product quality.