Pipe Jacking Construction

- Home /

- Fields of Application /

- Mining /

- Mine Water and Environmental Protection Stage

Pipe jacking construction is a core non-excavation technology widely used in urban infrastructure projects such as water supply and drainage pipelines, gas pipelines, and communication cable laying. It features minimal impact on ground traffic, buildings, and the surrounding environment, making it an indispensable construction method in modern urban construction. However, during the pipe jacking process, the drilling fluid (mud) plays a key role in lubricating the pipe wall, stabilizing the borehole, and carrying slag. The quality of mud treatment directly affects construction efficiency, project safety, and environmental protection compliance.

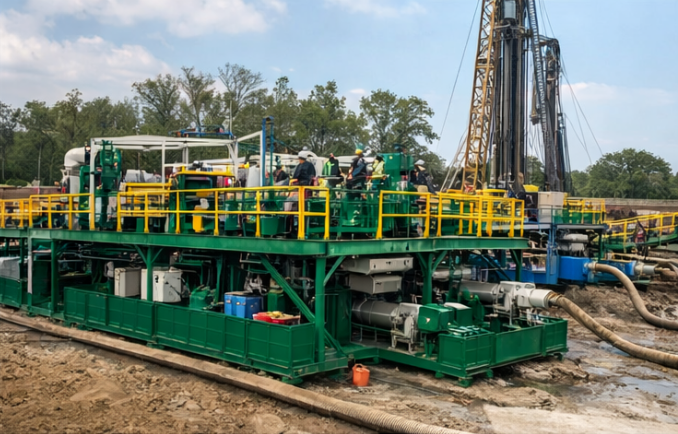

As a professional solids control equipment manufacturer, we provide reliable and customized mud treatment solutions specifically designed for pipe jacking projects. Our systems are engineered to separate solids from slurry efficiently, allowing the treated slurry to be reused in the excavation process. This not only reduces water consumption and disposal costs but also improves construction stability and overall project efficiency.

During pipe jacking operations, a jacking machine or micro-tunneling machine advances through the soil from a launch shaft to a reception shaft, while prefabricated pipes are pushed forward simultaneously. The excavation process generates a large volume of slurry mixed with soil particles such as sand, silt, and clay. If this slurry is not properly treated, it may lead to equipment wear, reduced jacking efficiency, unstable excavation conditions, and environmental pollution. Therefore, an efficient solids control and slurry treatment system plays a critical role in ensuring smooth and continuous pipe jacking construction.

In a typical pipe jacking slurry circulation system, the excavated slurry is pumped from the cutting head to the surface, where it passes through multiple stages of solids control equipment. The treated slurry is then stored, adjusted if necessary, and returned back to the jacking machine. Each stage of separation ensures optimal slurry performance and protects downstream equipment from excessive wear.

Request a Custom Pipe Jacking Construction Solution

1. Main Solids Control Equipment for Pipe Jacking

Equipment | Function | Application Value in Pipe Jacking |

Shale Shaker | Primary separation of large solids | Reduces solids load and protects downstream equipment |

Desander | Removal of sand particles (40–74 microns) | Minimizes abrasion and improves slurry quality |

Desilter | Removal of fine solids (15–44 microns) | Maintains stable slurry properties |

Decanter Centrifuge | Deep separation of ultra-fine solids | Enables slurry recycling and reduces waste volume |

Slurry Mixing & Storage System | Slurry conditioning and storage | Optimizes slurry performance and supports continuous operation |

Key Benefits:

Key Advantages:

- Customized system design based on project capacity and geological conditions

- High separation efficiency to ensure stable slurry performance

- Modular layout for easy transportation and fast installation

- Durable components suitable for continuous construction environments

- Reduced water consumption and slurry disposal costs

- Compliance with environmental and site management requirements

Operation & Service Support

In addition to standard models, KES Separation can customize pipe jacking mud systems according to customer-specific needs, such as adjusting tank volume, increasing the number of centrifugal pumps, or adding mud viscosity control devices, to adapt to different geological conditions (such as clay, sand, and gravel layers) and pipe jacking diameters (300mm-3000mm). With years of experience in solid control equipment R&D and production, KES provides one-stop services including pre-sales technical consultation, in-sales installation guidance, and after-sales maintenance support, ensuring that the equipment plays the best performance in every pipe jacking project.

Contact Us

Ready to enhance your beverage production efficiency and product quality? Contact KES Separation today to discuss a customized centrifuge solution for your beverage application.