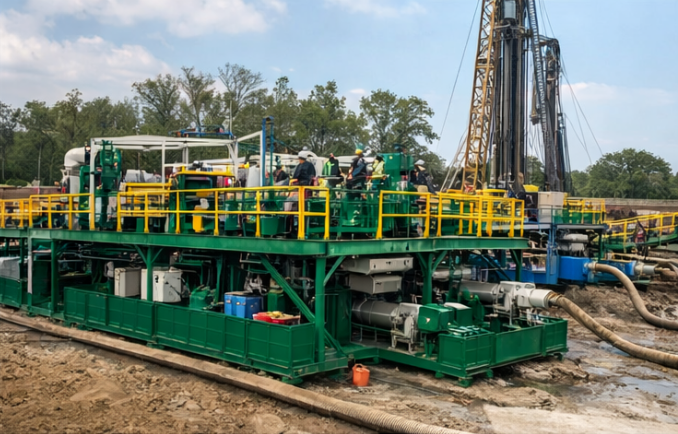

Recently, our company has successfully fulfilled a key order — custom-supplying 10 units of centrifuge feed pumps to key solids control players in Southeast Asia. Currently, all equipment has passed strict quality inspections and customer acceptance, and has been officially shipped and delivered.

The 10 sets Netzsch screw pumps are mainly applied in centrifuge feeding systems, serving critical solid control processes such as oil and gas drilling fluid treatment. Similarly to Netzsch Nemo pump, NOV Brandt Mono pumps are widely applied as centrifuge feed pumps. The Nemo pumps are equal to Mono pump with similar good performance.

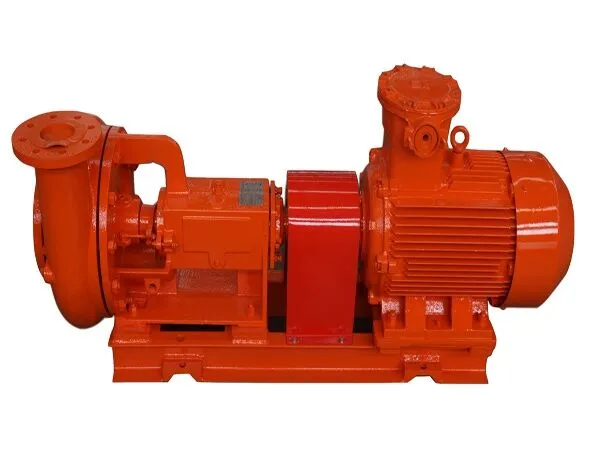

Notably, centrifugal pumps are also widely used as an important transfer pump in solid control systems. Their core advantages lie in adapting to high-flow feeding requirements, featuring a simple structure, low manufacturing costs, and convenient maintenance procedures. Our centrifugal pump is equal to NOV Brandt Mission 2500 pump and Mission magnum pumps. Besides, we can also provide replacement spare parts to Mission 2500 pump and Mission magnum pumps.

As the two mainstream pump types for solids control purpose in mud tank system, each have their own advantages and disadvantages, and need to be accurately matched according to the actual operating conditions:

| KESS Positive Displacement Pump | KESS Centrifugal Pump | |

| Suitable Medium | High-viscosity, high solid-content, and highly abrasive media | Medium-to-low viscosity, low solid-content, and low-abrasion media |

| Flow & Pressure Performance | Stable flow output with almost no pulsation; wide pressure range, suitable for high-pressure and precise feeding | Large flow rate but with certain pulsation; relatively low pressure, more suitable for low-pressure, high-flow continuous feeding |

| Shear Force Impact | Minimal shear force on the medium | Relatively high shear force generated by the rotation of the centrifugal pump impeller |

| Maintenance & Cost | Relatively high; regular replacement of wearing parts is required | High part universality; low procurement cost; long maintenance interval; low failure rate; convenient maintenance |

The successful conclusion of this cooperation not only reflects the customer’s high recognition of our company’s product quality and service capabilities, but also signifies our further in-depth cultivation in the Southeast Asian solid control equipment market.

As a mature solid control solution provider, we can offer customized product selection and supporting services based on customers’ specific operating conditions. For more information about the NETZSCH NEMO pump, solids control equipment or customized solutions, please contact our sales team.