Thermal Desorption Unit

Thermal desorption units are a critical technology for the treatment of oil sludge, offering an environmentally friendly and efficient solution for hydrocarbon recovery and waste management.

Description

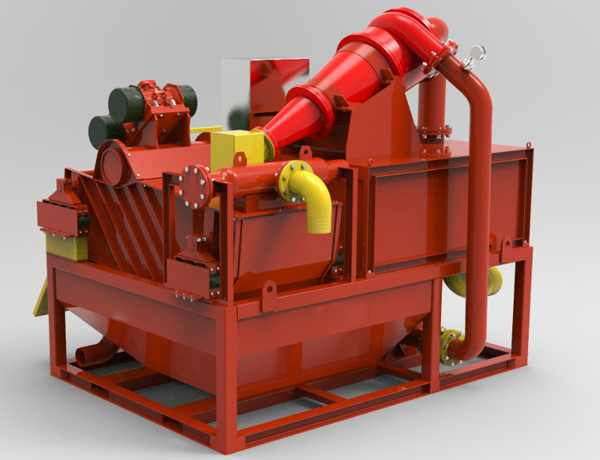

A Thermal Desorption Unit (TDU) is a specialized system used for the treatment of drilling cuttings, oil sludge, and hazardous waste material generated during oil exploration, production, refining, and storage. Oil sludge typically consists of a mixture of oil, water, solids, and heavy hydrocarbons, making it challenging to treat and dispose of safely. Thermal desorption is a highly effective method for separating and recovering hydrocarbons from the sludge while minimizing environmental impact.

How a Thermal Desorption Unit Works:

1. Feed Preparation:

- Oil sludge is pre-treated to remove large debris and homogenized to ensure consistent processing.

- The sludge is then fed into the TDU system, often using a screw conveyor or pump or excavator.

2. Heating and Volatilization:

- The sludge is heated in a controlled environment, typically in a rotary kiln or thermal desorption chamber.

- The temperature is carefully regulated (usually between 250°C and 600°C, depending on the sludge composition) to volatilize the hydrocarbons and water without causing combustion.

3. Separation of Components:

- The heat causes the oil and water to evaporate, leaving behind the solid residues.

- The vaporized hydrocarbons and water are then separated from the solids.

4. Vapor Treatment:

- The vapor stream is passed through a series of condensers and separators to recover the oil and water.

- Recovered oil can be recycled or reused, while the water is treated to meet discharge standards.

5. Solid Residue Handling:

- The remaining solids, now free of hydrocarbons, are cooled and discharged.

- These solids are often non-hazardous and can be safely disposed of or used in construction or landfilling.

6. Emission Control:

- Any remaining gases are treated using scrubbers, filters, or thermal oxidizers to remove pollutants before being released into the atmosphere.

Key Features of a Thermal Desorption Unit:

- High Efficiency: Capable of recovering up to 99% of hydrocarbons from oil sludge.

- Versatility: Can handle a wide range of oil sludge types and compositions.

- Environmental Compliance: Meets strict environmental regulations by minimizing emissions and hazardous waste.

- Scalability: Available in various sizes to accommodate different volumes of sludge.

Applications of Thermal Desorption Units:

- Oil Refineries: Treatment of tank bottom sludge and oily waste.

- Oil Exploration and Production: Cleaning up drilling mud and cuttings.

- Waste Management Facilities: Processing hazardous waste containing hydrocarbons.

- Soil Remediation: Treating contaminated soil from oil spills or industrial sites.

Advantages of Thermal Desorption:

- Resource Recovery: Recovers valuable oil for reuse, reducing waste and costs.

- Volume Reduction: Significantly reduces the volume of hazardous waste.

- Non-Combustion Process: Operates at temperatures below combustion levels, reducing the risk of harmful emissions.

- Compliance: Helps industries comply with environmental regulations for hazardous waste disposal.

Thermal desorption units are a critical technology for the treatment of oil sludge, offering an environmentally friendly and efficient solution for hydrocarbon recovery and waste management. By converting hazardous waste into reusable resources, TDUs play a vital role in promoting sustainability and regulatory compliance in the oil and gas industry.

Reviews

There are no reviews yet.