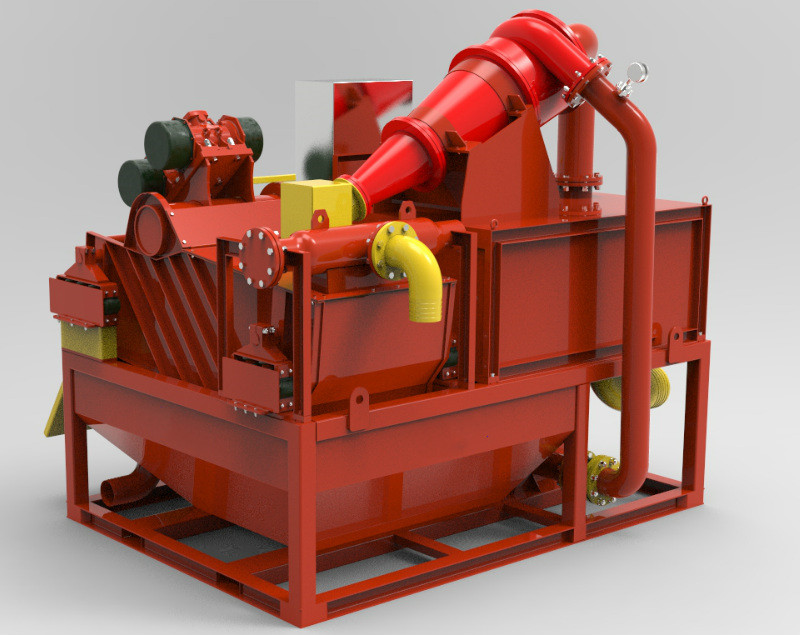

Centrifugal Pump

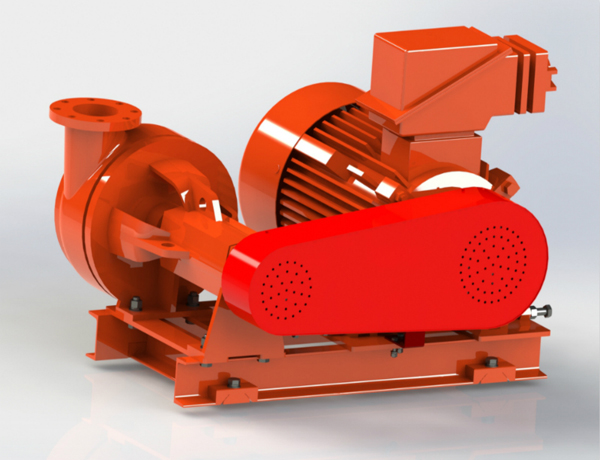

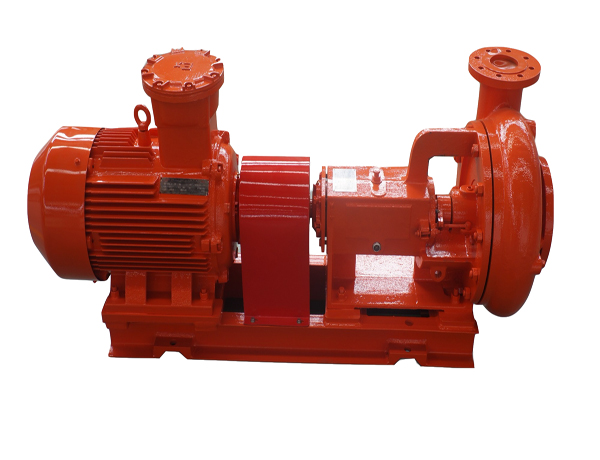

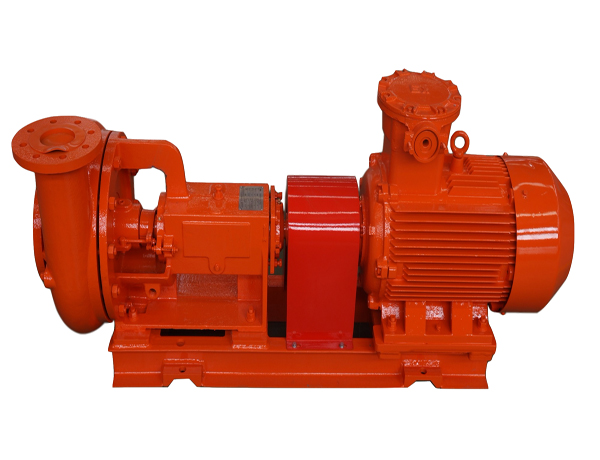

The 250 series centrifugal pumps handle drilling fluids and industrial slurries, including abrasive, high-viscosity, and corrosive media. With tungsten carbide mechanical seals, top-brand bearings, and an open impeller design, they offer high flow rates, long service life, easy maintenance, and reliable performance on both onshore and offshore drilling platforms.

Product Features

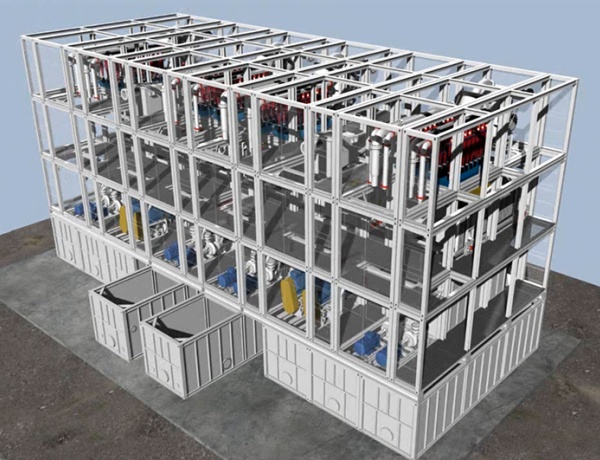

The 250 family of pumps is designed for pumping drilling fluid or industrial slurries. Our company adopts advanced design theory, and the centrifugal pump can be used to pump abrasive slurries, high-viscosity liquids, or corrosive slurries. Compared with competitors’ pumps, KES Separation centrifugal pumps have many technical advantages, including higher flow rate, anti-corrosion, anti-abrasion, high-temperature resistance, long life, easy maintenance, etc. The centrifugal pump is now widely used in onshore and offshore drilling platforms. We can also offer upstream and downstream products to provide pump system solutions to help clients achieve their work targets.

When working in a solids control system, the centrifugal pump can be used as a feeding pump for desander or desilter cyclones. The centrifugal pump can also work with a jet mud mixer. The centrifugal pump can work as a transferring pump when required at any point.

KES Separation centrifugal pumps normally adopt tungsten carbide mechanical seals, with international top-brand bearings. Centrifugal pump spare parts are interchangeable with most international brand pumps, which helps clients to source spare parts at lower cost. The centrifugal pump with an open impeller design lowers the axial thrust loads, making the pump easier to install, maintain, and repair.

Technical Parameters of Centrifugal Pump:

| Model | Flow (m3/h) | Lift(m) | Power(kW) | Impeller Speed | Impeller Diameter(in) | Weigh(kg) | Dimension(mm) |

| KSSB3×2-10J | 35 | 35 | 7.5 | 1450 (50Hz) | 10 | 445 | 1585x505x709 |

| KSSB3×2-9J | 35 | 35 | 7.5 | 1750 (60Hz) | 9 | 445 | 1585x505x709 |

| KSSB4×3-11J | 45 | 25 | 11 | 1450 (50Hz) | 11 | 464 | 1585x505x709 |

| KSSB4×3-9.5J | 45 | 25 | 11 | 1750 (60Hz) | 9.5 | 464 | 1585x505x709 |

| KSSB4×3-12J | 55 | 28 | 15 | 1450 (50Hz) | 12 | 482 | 1615x505x709 |

| KSSB4×3-10J | 55 | 28 | 15 | 1750 (60Hz) | 10 | 482 | 1615x505x709 |

| KSSB4×3-13J | 65 | 35 | 18.5 | 1450 (50Hz) | 13 | 530 | 1635x505x729 |

| KSSB4×3-12J | 65 | 35 | 18.5 | 1750 (60Hz) | 12 | 530 | 1635x505x729 |

| KSSB5×4-12J | 90 | 30 | 22 | 1450 (50Hz) | 12 | 620 | 1667x568x729 |

| KSSB5×4-10J | 90 | 30 | 22 | 1750 (60Hz) | 10 | 620 | 1667x568x729 |

| KSSB5x4-13J | 120 | 35 | 30 | 1450 (50Hz) | 13 | 642 | 1741x568x818 |

| KSSB5x4-11J | 120 | 35 | 30 | 1750 (60Hz) | 11 | 642 | 1741x568x818 |

| KSSB6x5-12J | 150 | 30 | 37 | 1450 (50Hz) | 12 | 766 | 1831x558x838 |

| KSSB6x5-9.5J | 150 | 30 | 37 | 1750 (60Hz) | 9.5 | 766 | 1831x558x838 |

| KSSB6x5-13J | 200 | 35 | 45 | 1450 (50Hz) | 13 | 786 | 1861x558x838 |

| KSSB6x5-10J | 200 | 35 | 45 | 1750 (60Hz) | 10 | 786 | 1861x558x838 |

| KSSB8x6-13J | 272 | 35 | 55 | 1450 (50Hz) | 13 | 896 | 1894x650x932 |

| KSSB8x6-11J | 272 | 35 | 55 | 1750 (60Hz) | 11 | 896 | 1894x650x932 |

| KSSB8x6-14J | 320 | 35 | 75 | 1450 (50Hz) | 14 | 1230 | 1968x650x942 |

| KSSB8x6-12J | 320 | 35 | 75 | 1750 (60Hz) | 12 | 1230 | 1968x650x942 |

Technical Features of Centrifugal Pump:

- The coaxial thickening design is adopted to reduce vibration and wear during the operation of the pump and to prolong the service life of the pump casing;

- The pump casing is made of wear-resistant ductile iron alloy, with higher wear resistance under tough conditions;

- Adopts international top-brand bearings with stable operation and long service life;

- The open impeller design effectively reduces the bearing load on the shaft and prolongs the service life of the bearings;

- The impeller is made of wear-resistant alloy ductile iron by precision casting, with a longer service life;

- An anti-loosening impeller lock bolt eliminates pump damage in case of improper motor hook-up;

- A high-quality mechanical seal is adopted to prevent pump leakage and reduce maintenance time;

- A replaceable sleeve prevents shaft wear;

- The base of the centrifugal pump adopts an integral cast base, providing greater stability during operation;

- All spare parts are interchangeable with international popular brand pumps, allowing the buyer to find parts locally more easily and reduce maintenance costs.

正右视图-2.jpg)