The TBM Machine Desanding Plant is an integrated slurry circulation and separation system designed to maintain stable slurry performance during TBM tunneling. It ensures efficient removal of solids, supports slurry recycling, and enhances construction efficiency while reducing operating costs and environmental impact.

| S/N | Product | Qty |

| 1 | Desander Cyclone | 1 |

| 2 | Shale Shaker | 1 |

| 3 | Centrifugal Slurry Pump | 2 |

| 4 | Electric Control Cabinet | 1 |

| 5 | Integrated Frame | 1 |

| 6 | Mud Tank (Integrated) | 1 |

1. Mud Water Separation

The mud water separation system is applicable to the mud purification and recovery of pile foundation works (including rotary drilling, percussive drilling, etc.), anti-seepage wall works (diaphragm wall, double wheel milling), mud water balance shield construction and mud water pipe jacking construction using mud retaining wall and circulating drilling technology. Greatly improve the reuse rate of waste mud, avoid the random discharge of mud, help customers reduce construction costs, civilized and environmentally friendly construction.

KES Separation shield tunneling desanding plant, can also be called TBM desanding plant or piling desanding plant or mud water separation plant or construction mud desander. The desanding plant has wide applications in construction mud treatment and engineering mud recycling. KES Separation Mud Water Separation system is a necessary equipment of foundation construction, used for pile foundation projects adopting slurry hole/tunnel wall supporting, rotary drilling rig, circular drilling technology; Diaphragm wall project and slurry purification recycling of slurry pipe-jacking construction, with the features of reducing construction cost, increasing construction efficiency. KES Separation Desanding plant can control the mud performance, increase drilling efficiency, save drilling cost and minimize environmental impact.

Product Features:

- Fully clean the mud, effectively control the mud performance index, reduce the sticking accidents and improve the drilling quality.

- Realize mud recycling and save mud making materials. Greatly reduce the cost of waste slurry transportation

- The shale shaker adopts double-layer screen design, with better purification effect than ordinary single-layer screen, simple operation and easy maintenance.

- Mud recycling reduces the impact on the environment and saves construction costs.

- The system design can operate continuously to improve the construction efficiency.

- The system adopts modular design, occupies a small area, and is easy to remove and maintain.

2. Shield Slurry System

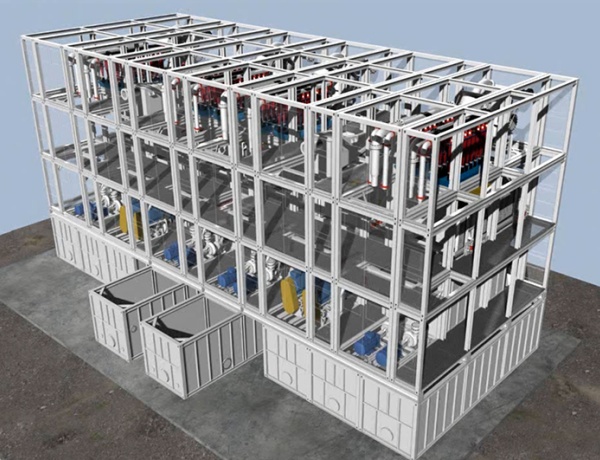

Combination with domestic and foreign engineering treatment experience and technology, KES Separation shield slurry circulating system provide slurry balance for TBM machine. It adopts a centralized visual control system, which can easily monitor the operating parameters of each running equipment. The modular design greatly facilitates the expansion of the system. A number of advanced separation technologies have been applied to effectively separate complex geological structures.

Product Features:

- Large processing capacity, 600-3600m³/H Mud circulation requirements for shield construction

- Advanced separation technology is adopted to ensure smooth tunneling of shield machines in complex geology

- Adopt active noise reduction and closed noise reduction structure to meet the requirements of urban construction at night

- Modular design of the overall structure greatly shortens the equipment installation cycle and makes it easy to expand with the project requirements

- Flexible design scheme to meet the requirements of urban construction site

- Fully automatic slurry mixing equipment is used to meet the rapid replenishment and emergency discharge of the shield circulation system and avoid construction risks

- Centralized control (MCC) system is adopted to realize equipment operation monitoring, adjustment, operation and fault visualization

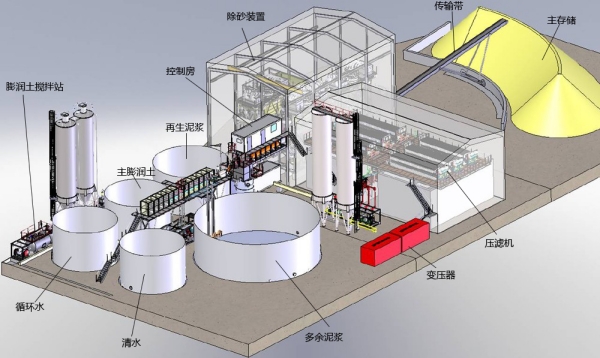

Slurry water separation process for shield tunneling

The slurry separation system process design needs to be tailored according to the project geological structure and shield machine parameters. We have professional process engineers for seamless project docking. The type selection of all equipment shall be strictly designed and calculated to combine the actual working conditions of the project.

KSTBM slurry separation system produced by our company is mainly applicable to ¢ 6m – ¢ 13.5m slurry balanced shield machine, meeting the requirements of 650-520m ³/ H Requirements for mud circulating treatment. KSTBM mud water separation station can perfectly meet the needs of tunneling technology. It can continuously separate the slurry suspension from the solid particles in the slurry loop. The combination of high exciting force screening equipment and low tangential point cyclone effectively reduces the water content of waste slag and the solid content of mud. The extremely small particles left in the mud have an important influence on the driving speed and daily footage and other parameters.

Common Features and System Integration

| System Type | Main Function | Key Features |

| Shield Slurry System | Slurry circulation supply and slurry balance control for shield tunneling operations | Centralized control, high automation level, adaptability to complex geological conditions, fast response |

| Mud Water Separation | Slurry purification, solid-liquid separation, and slurry reuse | Modular design, continuous operation, cost-effective, environmentally friendly |